...BUT THE LIGHTS WORK, AND I FIXED THE PROBLEM!!!!

After testing the lights with two SquareWears and two different tilt sensors, something weird was going on, especially since the code was written properly. So, while I was testing the lights and becoming frustrated that they were responding erratically, I noticed that, if I wiggled the strand or pushed down on it in certain places, the lights would switch on and off. This led me to think that there was maybe something wrong with the connections between each of the LEDs from one to the next. Audrey suggested soldering one section together to see if that worked to stabilize the lights, and it did! Ridiculously happy, I proceeded to spend an hour soldering about 110 connections with three strips per connection for a grand total of 300+ connections. Even though I'm not going to be using the entire strand, I wanted to solder all the connections for the next person to use the lights. I don't want them to have to spend time being confused as to why the lights were so unpredictable!

I tested the lights several times throughout this process to make sure that everything was still working properly, and I am relieved to say that I now have a consistent response from the strand.

Having finished that, it was time to make the skirt! I decided to hand-sew the lining into the existing chiffon skirt, mostly because I couldn't figure out the sewing machine and didn't want to come back to the lab later. I figured that it would be more efficient to use a method that I was familiar with, and it took less than an hour to sew everything in properly. Unfortunately, when I tried it on, I discovered that the fabric for the lining doesn't stretch like the chiffon does, so I had to unpick a few stitches. The main problem is that it's too long, so I'll cut the lining down to maybe an inch or so, just enough for the lights. Tomorrow, I'm aiming to embed the technology and start testing!

The grand total of hours for this? FIVE! But it was worth every moment. This was definitely the most satisfying work I've done on this project and, despite the long consecutive hours, I felt happy and productive and like I knew what I was doing. I honestly didn't think I'd get to that point, but I have, and I am so proud!

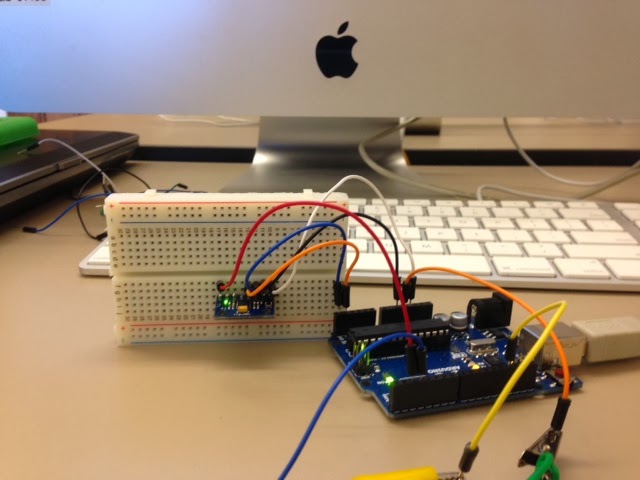

.JPG) |

| SquareWear testing with lights draped over a chair (out of view) |

.JPG) |

| Soldering the connections. Proud of the artsy photo :) I definitely had some scary moments with this because, sometimes, the soldering iron would burn/melt the plastic coating or not pick up the solder properly. All in all, no burns or injuries or bad connections, so I'd consider it a success! |

.JPG) |

| Testing successfully after properly soldering connections!! |

.JPG) |

| Sewn-in lining with taped-on lights. Managed to poke myself with the needle too many times. I'll be cutting down the lining length a bit so that I can actually wear the skirt without it puckering too much. |

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)